Description

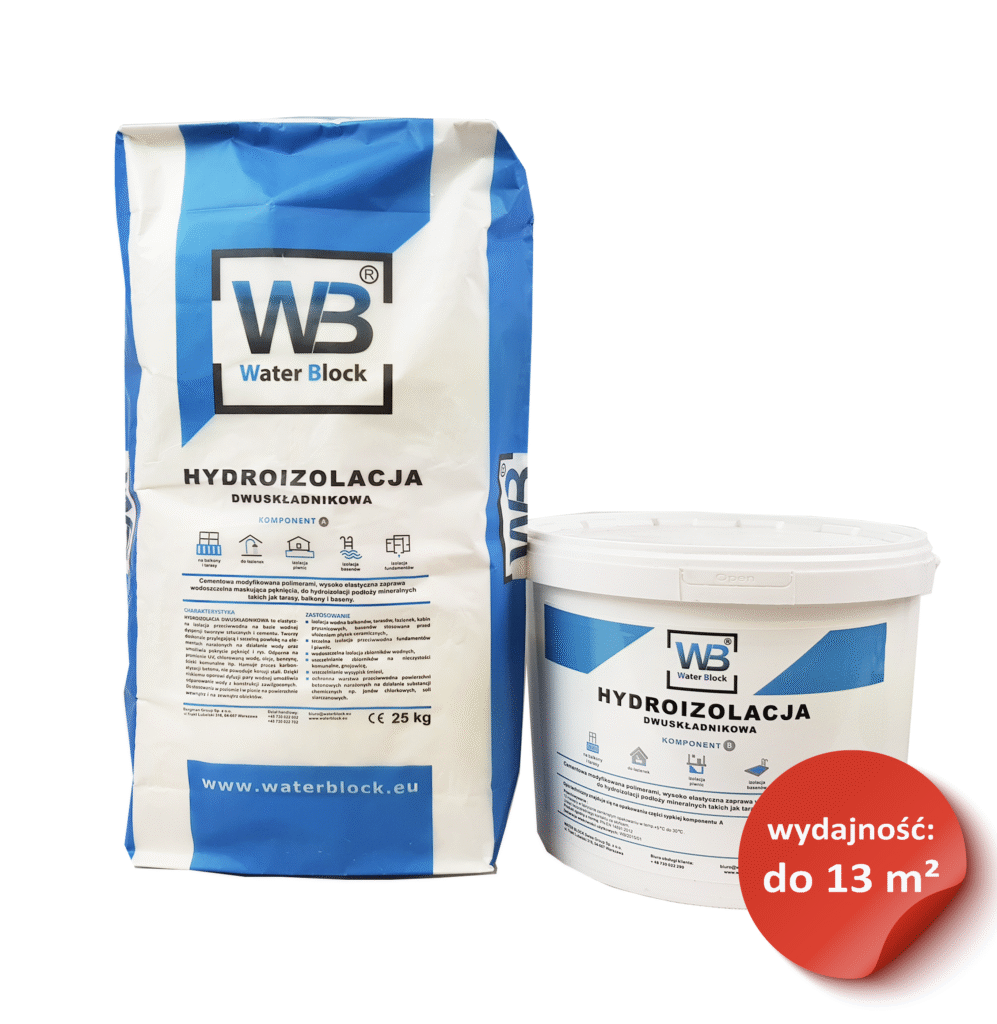

WB Waterproofing 2K - is a two-component, flexible waterproofing based on an aqueous dispersion of plastics and cement. It forms a perfectly adherent and watertight coating on parts exposed to water and allows cracks and scratches to be covered. Specially designed to resist both positive and negative water pressure. Resistant to UV rays, chlorinated water, oils, petrol, municipal wastewater, etc. Inhibits the carbonation of concrete and does not corrode steel. Thanks to its low vapour diffusion resistance, it allows water to evaporate from soggy structures. For use horizontally and vertically on indoor and outdoor surfaces.

PROPERTIES:

- Two-component sealant: Provides an effective and long-lasting seal.

- It has exceptional adhesion to all concrete surfaces and cement screeds, as well as to ceramic cladding, mosaics, natural stone, provided they are bonded to the substrate and properly prepared

- Resists positive and negative water pressure: Protects against water pressing from outside and penetrating into the interior.

- Frost resistance - the effect of frost does not reduce the water tightness of the coating

- Resistant to UV radiation and ageing

- Contains special synthetic additives: To improve the sealing properties and increase the adhesion of the adhesive to the tiles.

- Application on matt-moist substrates: Allows easy and quick application without the need to wait long for the surface to dry.

- Perfect substrate for ceramic cladding and ventilated terrace: Creates an ideal surface for further finishing work.

- Preventive protection against water and damp: Ideal for basements, garages and living areas, especially where external insulation cannot be used.

- Fast curing - can be recoated after 3 hours and ceramic cladding after 12 hours

- Recommended for old, damp buildings - vapour-permeability combined with water tightness makes the mortar ideal for insulating the building envelope of historic buildings

- Protection of the surface of reinforced concrete (reinforced concrete) - the 2 mm thick coating provides effective protection of the concrete surface against carbonisation and associated corrosion of the reinforcing steel.

Sample of WB 2K waterproofing

APPLICATION:

- insulation of terraces and balconies, swimming pools, bathrooms

- sealing of external basement walls and foundations, especially those at risk of shrinkage cracks

- sealing of concrete tanks for the storage of water, including drinking water,

- insulation of plasterboard, plaster or cement bases, aerated concrete blocks and waterproof plywood,

- sealing and smoothing of concrete surfaces subject to minor deformation under load,

- to protect plaster or concrete with shrinkage cracks from water penetration and aggressive weathering,

- protection of concrete columns and floor beams,

- protection of concrete surfaces exposed to seawater and chemical agents

- insulation of terraces and balconies, swimming pools, bathrooms

- sealing of external basement walls and foundations, especially those at risk of shrinkage cracks,

- works well as insulation against negative water vapour.

Performance:

1.7 kg/m2 per mm of layer thickness. The exact consumption of the product depends on the absorbency and structure of the substrate.

Consumption of materials:

Waterproofing WB 2k - enough in two coats 10 to 12 m2

Link to WB 2K waterproofing (small 15kg kit) - SEE

Substrate preparation:

Surfaces to be waterproofed with WB 2K waterproofing must be sound, compact, dry or damp, cleaned of dust, dirt, mould, algae, moss, old, flaky coatings, oil, cement milk, rust, efflorescence, infiltration, bitumen coatings and other substances reducing adhesion. All cavities and irregularities should be smoothed out with mortar. Highly absorbent substrates and substrates containing gypsum should be primed with a deep penetrating primer (WB Primer).

Product preparation:

WB 2K contains two separate packages: a liquid component and a dry (powder) component. Pour the powder component into the pack containing the liquid component while slowly stirring with a slow-speed mixer until a homogeneous lump-free mass is obtained (approx. 2 minutes). Allow the mixture to stand for 5 minutes and then stir again. Do not stir the mass by hand. Use the prepared mix within 1 hour.

Method of use:

Apply WB 2K to the substrate with a brush, steel float or spray equipment. Apply the first thin layer by rubbing firmly into the substrate in order to close the pores. Apply the second coat, if any, only after the first coat has set (after approx. 4 hours). The thickness of the layer applied in one application must not exceed 2 mm (recommended 1 mm) and the total thickness of all layers applied must not be less than 2 mm. The surface can be smoothed with a steel trowel within minutes of application.

In vertical and horizontal corners and in expansion joints, additionally fuse sealing tapes. Reinforce heavy-duty surfaces with glass fibre fabric.

Do not apply during precipitation. Protect freshly applied coatings from rain and frost for approximately 12 hours.

In particularly hot and dry conditions, protect against rapid drying with damp mats.

The laying of ceramic cladding can be started after 4-5 days.

Storage time:

24 months - powder component,

12 months - liquid component.

Packaging:

33 kg set

25kg - dry component

8kg - wet component